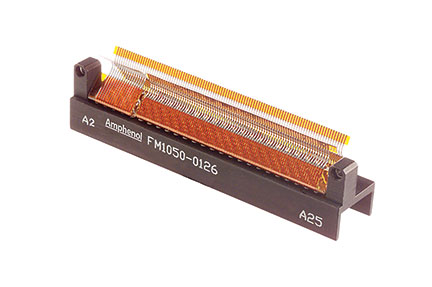

VIPER INTERCONNECT

The Viper connector is a VITA 60 backplane and daughtercard interconnect platform providing 63 differential signals per linear inch at 6.4 Gbps data rates. The VIPER connector has been ruggedized for Avionic, Ground and Naval applications.

- Fully footprint-compatible with VITA 60, VITA 46 and VITA 48 standards

- Hi-Speed: the VIPER is designed for 10 + Gb/s data rate performance

- 100 ohm impedance for differential pair configuration

- The daughtercard assembly is optimized for differential pair architecture on a 1.8mm x 1.35mm grid.

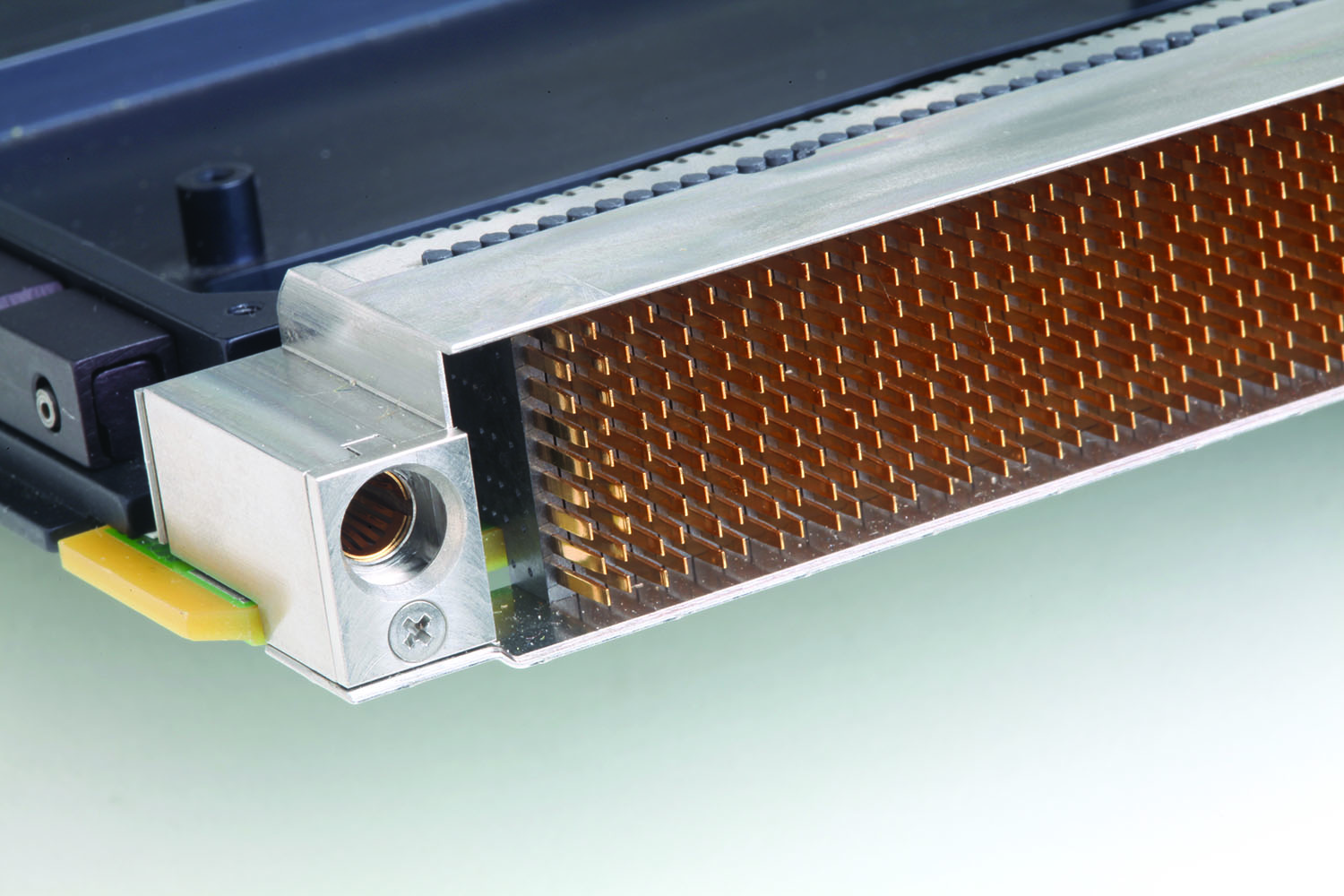

- The daughtercard is waferized, and provides single-ended and power wafer options integrated onto a stainless steel stiffener with stainless steel frame and keying elements

- The backplane has signal contacts that incorporate a highly reliable 4-point-of-contact beam design, and ground contacts which are robust compliant pin & contact fork design

- ±0.52mm nom. translation in fully mated condition

- ESD protection supports 2-level maintenance designs

- Flexible modular design is ideal for standard 3U and 6U applications, as well as unique custom configurations incorporating RF and fiber optic MT solutions

High-level vibration and mechanical shock protection. The VIPER connector platform offers the ability to scale from 80 Mbps to over 10 Gb/s while retaining the same Vita 46 platform slot pitch at 20.3mm to 25.4mm. Data Rate: 10 Gbps

- Differential Impedance: 100 ohms

- Differential Insertion Loss: –5 dB up to 5 GHz (10 Gbps)

- Differential Return Loss: – 5 dB up to 5 GHz (10 Gbps)

- Far End Crosstalk: –35 dB up to 8 GHz

- Near End Crosstalk: –33 dB up to 8 GHz

- Signal Contacts: 1 amp

- Power Wafer: 12 amps per wafer at 30° C T-Rise

- Compliant Pin to Plated Through Hole Resistance: 1 milliohm max

- Dielectric Withstanding Voltage: 500 volts RMS

- Insulation Resistance: 1000 megohms

- C4I

- Ground vehicles

- Naval

- Military/Aerospace Space